Get an Estimate!

"*" indicates required fields

Industrial and Commercial-Grade Concrete Polishing.

Transform your ordinary floors into resilient, sleek surfaces that stand the test of time with our concrete polishing services. We’re experts at delivering customized solutions for your facility with various slip resistance and gloss levels.

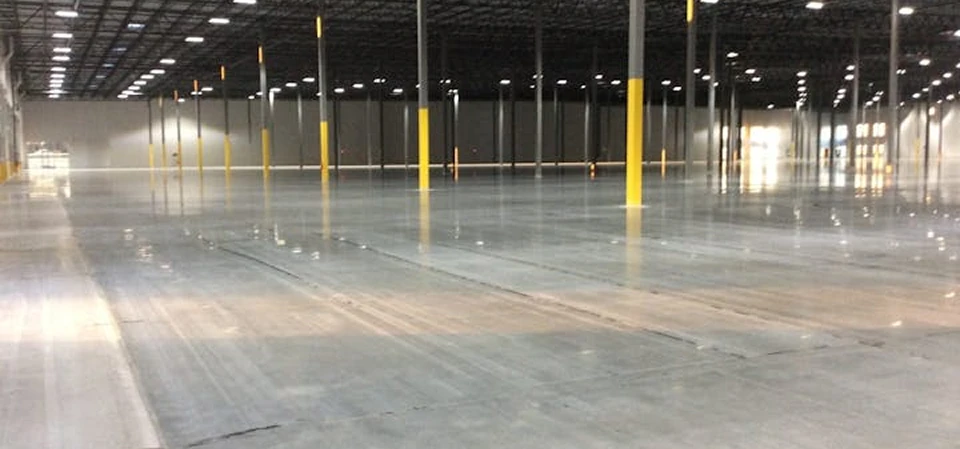

Concrete polishing transforms your ordinary floors into resilient, sleek surfaces that stand the test of time. Our service isn’t just about enhancing the appearance; it’s about delivering a flooring solution that combines cost-effectiveness with exceptional performance. From industrial warehouses to retail spaces, our polished concrete floors offer a low-maintenance, high-durability option that instantly elevates the look and feel of any environment.

Painters USA specializes in industrial and commercial-grade concrete polishing, offering a comprehensive solution to enhance operations, increase brightness, and protect your concrete flooring foundation. With our experienced team and state-of-the-art equipment, we deliver durable, low-maintenance results that meet the highest standards of quality and safety.

Optimize Functionality

Our specialists are ready to improve the aesthetics and functionality of your space, ensuring a blend of beauty, durability, and low maintenance. Ready to enhance your environment? We’re here to guide you every step of the way.

Problems You Have That We Can Solve

Happy Concrete Polishing Customers

Concrete polishing and more for Chicago-area PCA facilities

As a major producer of containerboard and other packaging / paper products, PCA’s plants require safe, durable flooring. Satisfied with past painting and industrial cleaning services, the maintenance manager of the Chicago Full Line Plant chose Painters USA for concrete polishing services to bring a section of flooring up to par with the rest of the facility.

Project Highlights

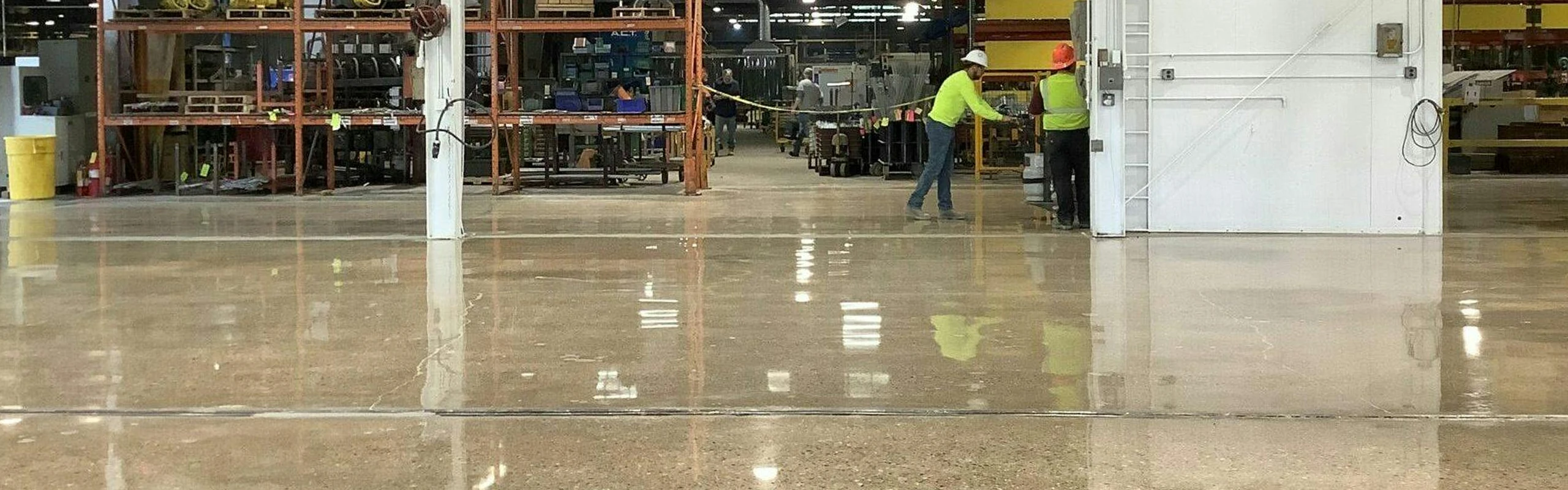

Revitalizing and protecting a machine-tooling production facility in northern Illinois

HCC has been in the equipment business for 100 years, designing and manufacturing agricultural equipment components for North and South American markets. The company relies on the safety record, quality work, and one-stop convenience of Painters USA for all their painting and concrete flooring needs.

Project Highlights

Strengthening forklift aisles for long-lasting endurance

Polished concrete is a durable, cost-effective flooring option for high-traffic areas like forklift aisles. Dayton Superior, the creator of Symonds concrete forming systems, turned to Painters USA for concrete polishing and line striping to protect and mark the concrete surface of their forklift aisles in a Chicago facility.

Project Highlights

See Concrete Polishing Projects We’ve Done

Achieve Safety and Compliance

Take a proactive step towards ensuring a safer workplace that meets all regulatory standards. Our concrete polishing solutions not only improve the look of your floors but also their safety and compliance with industry regulations. Don’t wait for accidents to happen; let us help you create a safer environment today.

Questions you should be asking

Our happy clients. Both big and small

Maximize Your Investment.

Achieve long-lasting, high-performance floors with minimal downtime and maintenance. Our expertly polished concrete floors are a smart investment, offering cost savings on maintenance and energy bills over time. If you’re looking for a flooring solution that delivers both on aesthetics and functionality, we have the expertise you need.